POSEIDON ST

Request product

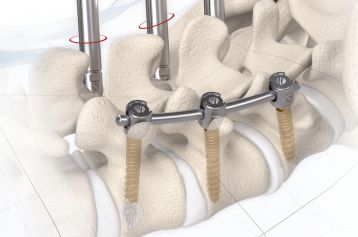

start requestMaterial defects – caused by tumours, fractures or infections – place great strain on the implants being inserted for reconstruction because of the need to resect weight‑bearing structures. The requirements for a stable structure for vertebral body replacement implants are adequate support for the cortical bone and reliable mechanics of the vertebral body replacement implant itself. With POSEIDON® ST the risk of subsidence is minimised by inferior and superior endplates that have the largest area possible, which also ensure the rotational stability of the implant.1 The reliable mechanics prevent dislocation of the implant caused by the decrease in stress in the endplates.

1An Ex Vivo Biomechanical Study Murat Pekmezci, MD, *Erik McDonald, BS, *Abbey Kennedy, MD, *Russell Dedini, MD, *Trigg McClellan, MD, *Christopher Ames, MD, † and Vedat Deviren, MD *, „Can A Novel Rectangular Footplate Provide Higher Resistance to Subsidence Than Circular Footplates?“, SPINE Volume 37, Number 19, pp E1177–E1181 ©2012, Lippincott Williams & Wilkins

The variability of POSEIDON® ST when placing the endplates on the base body enables the surgeon to freely choose the approach to treat defects caused by tumours, fractures or infections in the TH1 to L5 spinal segment. The endplates of POSEIDON® ST are made of structured titanium and are toothed, which anchors them into the inferior and superior endplates of the adjacent vertebral bodies after distraction, thus providing the necessary protection against dislocation without loading the less stable central core of the vertebral body. The open-pore titanium grid structure of the POSEIDON® ST endplates optimises the osseointegration behaviour. The inserted cage, combined with additional posterior instrumentation, leads to immediate biomechanical stabilisation. The overall structure of the POSEIDON® ST is made up of a base body that can be distracted in situ and two endplates. If required, the implant construct can be expanded by an extension at either the superior and / or the inferior end of the base body. The expandable modules are available in five different heights ranging from 18 to 49 mm. Including the extension modules, a height of up to 89 mm can be covered (height excludes the endplates). Thanks to the narrow base body with a diameter of only 16 mm, there is plenty of space available for fusion material such as harvested bone or synthetic bone graft material, e.g. KAINOS® +, and they can be combined with a large selection of endplates in different sizes and angles. This highly modular design of POSEIDON® ST provides the surgeon with a great degree of flexibility so that the implant can be customised as precisely as possible to the patient’s individual situation, fully utilising the maximum possible area2 of the bone–implant interface to achieve rotational stability of the implant. The locking screw secures the cage at the desired height.

2YOUSSEF MASHARAWI, 1, 2 KHALIL SALAME, 3* YIGAL MIROVSKY, 4 SMADAR PELEG, 2 GALI DAR, 2, 5 NILI STEINBERG, 2, 6 AND ISRAEL HERSHKOVITZ2, „Vertebral Body Shape Variation in the Thoracic and Lumbar Spine: Characterization of Its Asymmetry and Wedging“, Clinical Anatomy 21: 46–54 (2008)

Secure construction

Highly modular design

Sophisticated endplate design

Open, macroporous titanium structure*

SIGNUS modular solution

Manufactured from a biocompatible titanium alloy (Ti-6Al-4V) with proven strength.

The open, porous structure of ST implants increases the surface area for new bone cells to settle, thus increasing the contact surface between the implant and the end plate of the adjacent vertebral body. In combination with the surface roughness of the implant, a high primary stability and a significantly reduced risk of migration can therefore be achieved. This is additionally favoured by the open and interconnecting porosity, which enables successful grafting of endogenous cell material and its propagation.

Click here for detailed ST material information.

Here you get to the eifu of POSEIDON ST.