ROTAIO

Request product

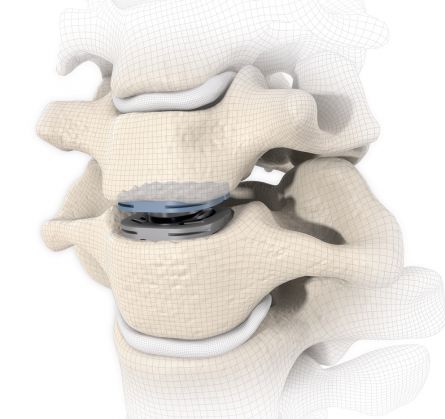

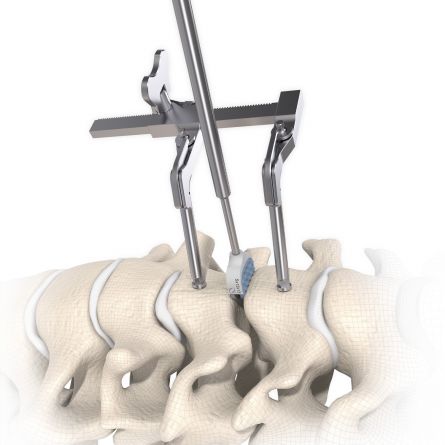

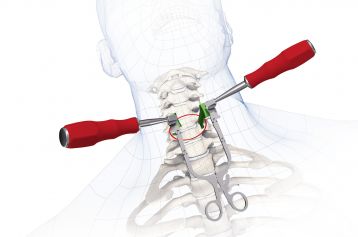

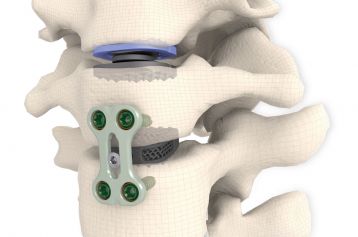

start requestThe ROTAIO® disc prosthesis was developed for the specific requirements of the cervical spine (C3 – C7). Despite the highly complex joint kinematics of ROTAIO®, the surgical implementation remains simple. ROTAIO® is implanted ‘in one piece’ using the proven Smith–Robinson technique.

The prosthesis is available in various footprints and heights to enable adaptation to different patient anatomies.

ROTAIO® is inserted in the C3 – C7 spinal region. As well as the simple implantation procedure, the large footprints of the disc prosthesis maximise the area of contact with the vertebral body. This helps to prevent unwanted fusion of the segment. We have retained the product features of our proven RABEA® cages in the form of the tried and tested endplate serrations. This ensures secure primary stabilisation of the segment while at the same time minimising bone resection.

To reproduce the natural movement of a healthy intervertebral disc – that is the goal of ROTAIO®. This means not merely the preservation but above all the quality of movement of a natural intervertebral disc is prioritised. Along with rotation, flexion/extension and lateral bending, ROTAIO® therefore enables the option of uncoupled translation and thus of physiological facet-guided segment movement.

ROTAIO® can thus be summed up in one sentence:

implantable like a cage – moves like a Disc.

Safety oriented prosthesis design

Tested mechanics

Increased roughness in conjunction with proven SIGNUS toothed cage design

Physiological mobility

Pre-mounted, in sterile packaging

Pre-mounted, in sterile packaging

The ROTAIO® disc prosthesis is made up of several material components that offer a number of benefits for application. A cobalt-chrome-molybdenum (CoCrMo) alloy was selected for the bearing surfaces. This metal is characterised by very good biomechanical and tribological properties. The endplates are manufactured from a titanium alloy (Ti-6Al-4V) that improves the osteointegration thanks to the specially roughened surface.

Here you get to the eifu of ROTAIO.